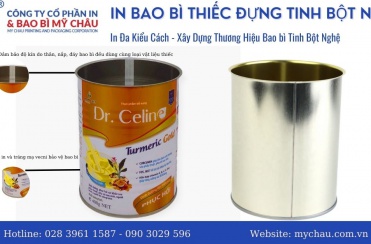

At My Chau Printing And Packaging Corporation, we specialize in designing and manufacturing custom tin boxes in a wide variety of models, sizes, and shapes, meeting diverse packaging needs across multiple industries.

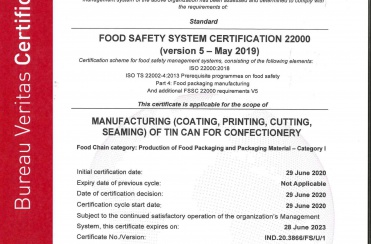

With a modern, closed-loop production line from coating – printing – can making, combined with a team of highly skilled technicians, My Chau guarantees premium-quality products that are food-safe and environmentally friendly.

Advantages of Custom Tin Box Production at My Chau Printing And Packaging Corporation

-

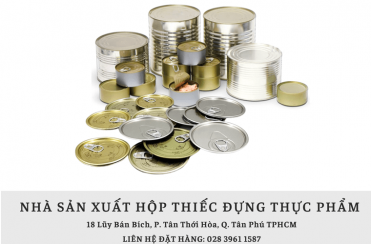

Wide range of sizes & shapes: round, square, rectangular, 2-piece cans, 3-piece cans

-

Creative printing design with customizable colors, logos, and patterns

-

High-grade tinplate material, corrosion-resistant and food-safe

-

Flexible order quantities, from small to large, with fast turnaround time

-

Suitable for multiple industries: infant formula, condensed milk, confectionery, tea & coffee, nuts, processed foods, seafood, industrial chemicals, and more

???? With over 45 years of experience and being one of the leading metal packaging manufacturers in Vietnam, My Chau Printing And Packaging Corporation is committed to delivering professional – creative – sustainable tin box packaging solutions that make your products stand out in the market.

Custom Tin Box Processing

We believe tin packaging represents the identity of your brand. The practicality and beauty of custom-designed tin packaging lie in eye-catching design, vibrant printing colors, and outstanding durability. A well-crafted tin package can become a true piece of art for your brand.

Custom tin boxes are versatile and can be used for packaging virtually anything – food containers, confectionery tins, industrial cans, spice tins, cosmetic tins, biscuit tins, chocolate tins, and more. Our printed tin box MOQ starts from just 5,000 cans!

Tin boxes are also an excellent marketing tool, giving your product a premium look and ensuring a bold impact on consumers.

Custom Tin Printing

In today’s highly competitive market, packaging suppliers are focusing on innovations in materials and coatings to deliver cost-efficient, eco-friendly, and lightweight packaging solutions.

Our expertise, combined with sharp and unique printing techniques, allows us to provide highly customizable metal packaging. The combination of tin box shapes with printing effects creates distinctive packaging that stands out and is easily recognizable to consumers.

A product packaged in a custom tin box instantly enhances its value, turning it into a premium item.

Printing Process

Our printing production line typically includes tinplate input, offset printing machines, coating equipment, and drying rooms. The tin printing process is carried out through the following steps:

-

Interior Coating

Depending on the food inside, tin cans require an inner coating to prevent corrosion. We use Non-BPA food-safe coating that complies with European standards. -

Primer / White Base Printing

Tinplate is coated with a white base before can forming. This primer must ensure high adhesion and durability to prevent cracking or peeling during can making (rolling, welding, flanging, seaming). A varnish layer is then applied to enhance gloss and protection. -

Printing

Tinplate is printed using offset printing technology, as its smooth surface allows for excellent ink absorption. A layer of protective varnish is applied afterward to improve gloss and scratch resistance.

Why Choose Custom Tin Boxes?

In a highly competitive market, brand owners constantly seek advanced forming and printing technologies to enhance the natural beauty of metal packaging. However, challenges remain in adopting the latest techniques, especially with thinner tinplate.

Our in-depth knowledge of color separation, printing techniques, and metal decoration constraints ensures high-quality results that meet brand expectations. We combine innovation with strict quality control to deliver packaging that is both functional and premium.

Size & Quantity Guidelines

-

MOQ: 5,000 cans

-

Free mold cost (for available molds)

-

Printing options: Metallic silver ink (Pantone 877C) can be used standalone or with CMYK to create metallic effects – best applied as solid colors.

Available Sizes:

-

Diameter: 52 – 185 mm

-

Height: 52 – 356 mm

✨ At My Chau Printing And Packaging Corporation, we design and produce custom tin packaging that not only protects your products but also elevates your brand image, giving you a competitive edge in the global market.

CONTACT US FOR SAMPLES:

Simply leave your details (contact number, specifications, and product information), and we will send you free samples.

???? Factory Address: 18 Luy Ban Bich, Tan Thoi Hoa Ward, Tan Phu District, Ho Chi Minh City, Vietnam

???? Hotline: 096.8899.250

???? Email: info.mychau@gmail.com