METAL PACKAGING PRODUCTION COMPANY

As a manufacturer of metal packaging, tin boxes. My Chau has R&D, production of tin boxes and automatic can production lines, closed from printing/coating to rolling cans. We have always focused on developing new products, improving product quality, production efficiency and product innovation for the past 23 years. Our metal packaging and tin cans are manufactured with modern technology by highly skilled staff. For many years, My Chau has focused on providing a variety of metal packaging for many different industries such as food, beverage, pharmaceutical, agricultural products, dried fruit, processed food, industry. Paint industry, chemicals, household goods, spices, candles

Established in 1957, formerly a Canning Factory. In 1976, it changed its name to My Chau Food Export Factory.

In 1999 with the new name "My Chau Printing & Packaging Joint Stock Company". With more than 300 employees and more than 200 loyal customers. We always ensure that the production plant and infrastructure meet the standards and regulations on food quality, safety and hygiene. Health, safety, food hygiene, environmental protection and social responsibility are always prioritized and guaranteed.

My Chau Metal Packaging Company is continuously improving its quality to lead the Vietnamese market in coated printing and metal packaging products, replacing imports, aiming for global export.

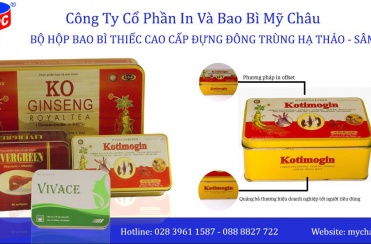

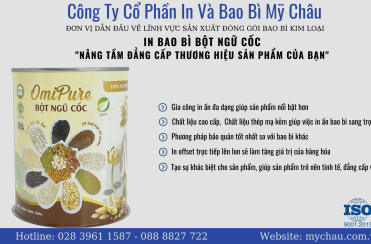

My Chau Printing & Packaging Joint Stock Company specializes in supplying tin cans for the food industry, ready-to-eat foods, coffee, tea, powdered milk packaging, confectionery, paint industry, home appliances industry and warranties for the Who needs Tin Boxes, Tin Cans, Food Tins, Iron Canned Cans. You can also find other packaging and printing solutions like tin cans, food cans, metal tin cans at competitive prices. Let us help you find solutions for your product packaging

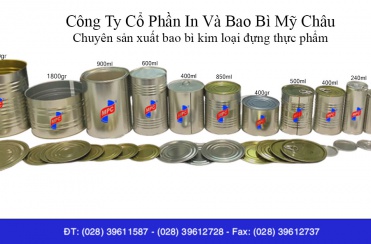

We have cooperated with companies in the fields of chemicals, agriculture, seafood, beverages, confectionery, pharmaceuticals, food containers and product packaging. We are a metal packaging supplier and manufacturer that solves each partner's specific problems. From 0.25L cans to 20L cans for paint cans, 155gr to 3000gr for food tins....

What is metal packaging?

Metal is Da Dang in terms of packaging. Packaging provides excellent product protection and physical barrier, shape, size and design. The most used metals in packaging are aluminum and steel.

The role of metal packaging

The main role of metal and food packaging is to protect food products from external and internal influences and spoilage, to contain food and to provide consumers with information on the composition and nutrition of food. nursing. Traceability, convenience. The goal of food packaging is to contain food in a cost-effective manner that meets industry requirements and consumer expectations, maintains food safety, and minimizes its impact on the environment. school.

External product protection: Some products need to be stored in dark packaging and away from sunlight or other light sources. Whether you use aluminum or steel, the packages are not transparent and do not let sunlight into the product inside. Metal packaging can also be airtight, keeping out oxygen that can damage the product.

Non-toxic to food, Does not change quality, taste, strange color for food. Resistant to odors, air, grease and bacteria penetration, High pressure resistance

METAL PACKAGING?

Top Benefits of using metal packaging:

The company that produces metal packaging especially the food industry, especially the canning industry, ensures that the food preservation process is carried out correctly and efficiently by using metal packaging. type. Metal food containers and easy-to-open lids offer many advantages from quick production to easy transport.

Food contained in metal packaging does not need any additives. Food in the packaging helps preserve and preserve the original taste for up to 3 years

The weight of the metal packaging is low and the resistance is high. Tin packaging is resistant to physical impact

ADVANTAGES OF PRINTING METAL PACKAGING FOR US FOOD

Multi-color printing increases the popularity of metal packaging, supporting product marketing activities Metal packaging can be produced in almost any size and form, so products can be packaged food products with desired weight

The way metal packaging can be sealed and heat treated allows for sterile, pasteurized food products.

Metal packaging has good barrier properties against gases, light and odors as well as high strength. Canned foods have the longest shelf life of all packaged foods. Because Metal Packaging is heat pasteurized or sterilized after canning. In addition, metal packaging has the highest recycling rate among all types of metal packaging

FUNCTIONAL METAL PACKAGING

Metal packaging has high temperature resistance and high heat transfer capacity, so foods of all kinds can be canned, pasteurized or sterilized with appropriate modes to ensure safety and hygiene.

High mechanical strength

Light, convenient for transportation

Ensure tightness because the body, lid, and bottom can all be made of the same material, so the packaging is not aging over time.

Resistant to normal light as well as ultraviolet rays affecting food

Metal packaging has high temperature resistance and high heat transfer capacity, so foods of all kinds can be canned, pasteurized or sterilized with appropriate modes to ensure safety and hygiene.

ROLE OF METAL PACKAGING

The main role of metal packaging such as canned food, industrial, metal packaging in daily life is to protect products and food from external and internal influences and damage, to contain foods and provide consumers with ingredient and nutritional information. Possibility of origin on the packaging, convenience. The goal of food packaging is to contain food in an efficient way that meets industry requirements and consumer expectations, maintains food safety, and minimizes environmental impact.

Using metal for your product packaging offers many benefits, your customers and the product itself.

5 benefits of using metal packaging include

External product protection: Some products need to be stored in dark packaging and away from sunlight or other light sources. Whether you use aluminum or steel, the packages are not transparent and do not let sunlight into the product inside. Metal packaging can also be airtight, avoiding oxygen that can damage the product.

Easy to transport

Convenient

Protect the product inside for more than 3 years

Convey information on packaging

Increase product value, high-end positioning

Protecting the product inside: This is the most important role because it helps to protect both the quality and quantity of the product. In addition to preventing dust from coming into direct contact with the product, the packaging also helps prevent the product from being strongly affected by outside influences such as impact, product deformation. Metal packaging can also be airtight, avoiding oxygen that can damage the product. Does not change the quality, taste or color of food. Resistant to odors, air, grease and bacteria penetration, High pressure resistance, no rust

Safety: Because the metal is sterilized, the tin cans are put inside, so it's safe to use with food. There is a possibility that certain metals can leach into certain types of products, such as aluminum seeping into acidic foods. But that can easily be prevented by lining the metal with a coating.

Attractiveness: Metal packaging is more than just utilitarian. It can also look good. Beverage cans can be decorated with the brand's logo and in a variety of colors, making the product stand out on the shelf. Metal tubes used to package lotion or beauty products look shiny and eye-catching, compared to other packaging

How to pack metal packaging - Direct Printing On Metal Packaging

+ Printing capabilities "Print your way"

+ Manufacturer's information

Instructions for use and storage of the product

metal packaging

1. Impressions of design, print color, style, size, size

2. Expression of product quality

3. Increase product value

4. Brand Impressions

Metal packaging – The “Look” point that affects the arising needs of customers

+ Packaging not only protects the product, but also helps to convey the manufacturer's messages to consumers, while metal packaging creates confidence in product quality and can be printed directly on metal. type

+ Protect brand image

+ Promote corporate brand to consumers

+ Honoring the beauty and class of product packaging

MATERIAL PACKAGING PRODUCTION SECTOR

Print, varnish on iron, aluminum

Producing, processing all kinds of metal packaging, printing metal packaging

Metal food packaging

Industry tin cans for paints, glues, cans for chemicals, solvents, water-based paints, oil paints, lubricants, printing ink

Metal box, round box, square box, rectangular box

Cake tin box

Tin box for coffee, tea, nuts

Canned fruit, peach, pineapple, longan, pineapple, papaya, mango, corn, mushroom

Tin cans for powdered milk, metal packaging for condensed milk

2-piece can of tuna, sardine, herring, crab, shrimp, ...

Prepared food packaging

metal food packaging

Print product packaging

Print paint packaging

Printed confectionery packaging

Print coffee packaging

Printed tea packaging

Print food packaging

Print paint cans

Print bottle cap

For more information please contact us:

Factory Address: 18 Luy Ban Bich, Tan Thoi Hoa Ward, Tan Phu District, HCMC

Hotline: 028 3961 1587 VND

Get a free quote: 0903 385 794

Email: Congtybaobimychau@gmail.com