Canned Food Packaging

1. Overview

Canned food packaging is widely used in the beverage and food industry, with common products such as coffee, juice, milk tea, beer, canned meat, poultry, seafood, fruits, and vegetables. This is a convenient form of food, processed, sealed, sterilized, and preserved in metal cans to extend shelf life and meet international export standards.

Canned food has existed for nearly a century and continues to evolve thanks to industrial advancements and rising consumer demand. Production technologies have been constantly improved—from raw material selection, cleaning, and processing to filling, sterilization, and sealing—ensuring higher quality, safety, and taste.

2. Basic Processing Workflow

The general process of canned food production includes:

-

Selection and cleaning of raw materials

-

Peeling and color protection

-

Cutting and preliminary processing

-

Filling and adding supplementary ingredients

-

Sterilization, exhausting, and cooling

-

Sealing and final packaging

Among these, sterilization – microbial control – sealing are the most critical steps, directly affecting product quality, shelf life, and taste.

3. Microbial Contamination in Canned Foods

Sources of contamination

-

Raw animal and plant materials inherently contain microorganisms.

-

Contamination may occur during processing, transportation, storage, distribution, or consumption.

-

Microbes may spread through water, air, people, animals, equipment, and the factory environment.

Common spoilage microorganisms

-

Low & medium-acid canned foods (pH > 4.5): Bacillus stearothermophilus, Clostridium saccharolyticus, Clostridium nigricans, Clostridium botulinum, Clostridium sporogenes.

-

Acidic canned foods (pH 3.7 – 4.5): Bacillus coagulans, Clostridium butyricum, Bacillus polymyxa, etc.

-

High-acid canned foods (pH < 3.7): Lactobacillus, yeast, molds, pectin-decomposing bacteria.

Main causes of contamination

-

Improper pH adjustment allowing microbial growth.

-

Incomplete exhausting before sealing, leaving residual air.

-

Poor sanitation standards for environment and equipment.

-

Factories with poor air-tightness, excessive dust, contaminated air.

-

Incorrect operating procedures, leading to secondary contamination.

4. Disinfection & Sterilization Solutions

Microbial control is essential to ensure food safety. An ideal disinfectant should:

-

Be colorless, odorless, tasteless, non-toxic, residue-free, and non-corrosive.

-

Be biodegradable and environmentally friendly.

-

Effectively eliminate a wide spectrum of microorganisms.

-

Remain stable under various conditions, dissolve easily in water, and be simple to apply.

For example, Biotec disinfectant (EU origin, HACCP and EU-certified):

-

Effectively eliminates over 130 harmful microorganisms.

-

Safe for humans and animals, does not alter product flavor, color, or pH.

-

Flexible application: sterilization of tools, surfaces, equipment, air, and pipelines.

-

Easy to use, no need for costly equipment investment.

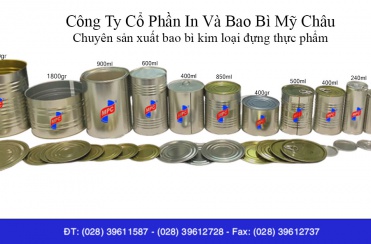

5. Two-Piece Cans

A two-piece can consists of a body and bottom formed from a single sheet of metal by deep drawing, with the top end seamed on to complete the package.

Advantages

-

No side seam, ensuring tight sealing and reduced material waste.

-

Full-surface printing and decoration possible.

-

Higher production efficiency compared to three-piece cans.

Disadvantages

-

Requires high-quality, uniform material.

-

Involves significant investment in technology, machinery, and tooling.

Classifications

-

By depth: shallow-drawn and deep-drawn cans.

-

By material: aluminum and steel (tinplate) two-piece cans.

-

By manufacturing method: Draw & Iron (DI) and Draw & Redraw (DRD).

-

By shape: round and irregular-shaped cans.

Among these, DI and DRD cans are the most widely used.