WHAT IS BOXING?

Canning is a method of preserving the inside of a product that involves placing food in cans or similar containers and heating it to a temperature that destroys spoilage organisms. During this heating, air is forced out of the can and prevents air from returning to the product. During the canning process, air is expelled from the jar and a vacuum is formed as the jar cools and seals.

WHY BOXED?

Suitable for high and low acidic foods

Prevent pollution

Extend shelf life

6 Steps Boxing Includes Several Stages:

Cleaning typically involves passing raw food through a container of water or under a high-pressure water jet, and then placing the intended food into the tin.

Almost all vegetables and some fruits require blanching in hot water or steam, which serves as an additional or final cleaning action.

Filling of food into cans is done automatically by machines

As soon as the cans are sealed, they are closed and sealed

The sealed containers are then sterilized, i.e. the food is heated to a high enough temperature and for a long enough time to kill all organisms.

The tin cans are then cooled in cold water or air, after which they are labeled

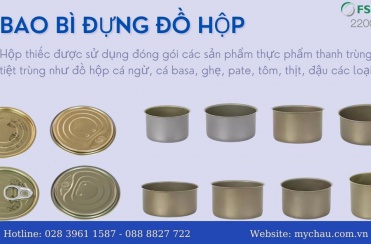

APPLICATION

Hot water canning can be used for highly acidic foods such as

Fruit tin box

Vegetable tin box

Pressure canning can be used for low-acid foods such as:

Kinds of meat tin box

Seafood, crabs, crabs, shrimp and squid

Poultry tin box

Milk Products tin box

Vegetable tin box

Tin box

Packing method by metal packaging

Hot water canning method, the tins close the food in boiling water, cooked for a certain time

Canning, a method of preserving food from spoilage by storing food in an airtight container and then heat-sterilizing it. Process the food inside the tin can, heat it to a certain temperature and maintain the heat for a certain time, then the box is sealed until use. Why food so treated doesn't spoil: the heat kills the microorganisms in the food, and the sealing prevents other microorganisms from entering the tin. The use of tinned iron cans instead of bottling European canning methods followed in the United States, and that country eventually became the world leader in both automated canning processes. and produce total canned goods. Science-based canning process by describing heating requirements at specific time temperatures for canned food sterilization.

Preserving canned vegetables and fruits at home

Originally, cans consisted of a sheet of tin-plated iron rolled into a cylinder (called the body), on which the top and bottom were manually soldered. This form was superseded in the early 20th century by the modern toilet can, or open lid, whose constituent parts are joined together by interlocking folds that are either crimped or pressed together. Polymeric sealing compounds are applied to the end, or the cap, seam and body seams can be externally sealed by welding. Modern tin cans are made of 98.5% sheet steel with a thin layer of tin (eg western iron). It is produced on a fully automatic machine line at a rate of hundreds of cans per minute.

Most vegetables, fruits, meat and dairy products, and processed foods are packaged in tin cans, but soft drinks and many other beverages are now usually packaged in aluminum cans, which are lighter and do not rust. . Aluminum cans are made by impact extrusion; The body of the can is punched piece by piece from a single aluminum plate by a die. This seamless piece, which has a rounded bottom, is then covered with a second piece as its lid. The tabs used in pop-top cans are also made of aluminum. Bimetallic canning is made of aluminum body and steel lid.

Canning plants are often located near the growing area of the packaged product, because it is desirable that the food be canned as quickly as possible after harvest. The canning process itself consists of several stages: cleaning and further preparing the raw food ingredients; blanching it; filling containers, usually in a vacuum; closing and sealing containers; sterilization of canned products; and label and stock the finished product. Cleaning typically involves passing raw food through a water tank or under a high-pressure water jet, after which vegetables or other products are cut, peeled, shredded, sliced, sorted, pickled, or pureed. , etc. Almost all vegetables and some fruits need to be blanched in hot water or steam; This process softens vegetable tissues and makes them pliable enough to be tightly packed, and is used to inactivate enzymes that can cause undesirable changes in foods prior to canning. Blanching also serves as an additional or final cleaning action.

The filling of cans is done automatically by machines; The can is filled with solids and in many cases with liquid (usually brine or syrup) to replace as much of the air in the can as possible. The filled cans are then passed through a hot water or steam bath in the discharge box; this heating expands the food and expels any remaining air; therefore, after sealing, heat sterilization, and cooling of the can, the contraction of the contents creates a partial vacuum inside the container. Certain products are vacuum packed, whereby the cans are released mechanically by specially designed vacuum sealers.

As soon as the cans are empty, they are closed, sealed; a machine that places the cap on the can, curls the cap on the can and the flange on the body of the can into place and then flattens it together. The thin layer of the original sealing compound present in the rim of the cap is dispersed between the metal layers to ensure a tight seal. Then the sealed containers are sterilized; i.e., they are heated to a high enough temperature and for a long enough time to kill all microorganisms (bacteria, molds, yeasts) that may be present in the food. Heating is done in a high-pressure steam kettle, or crucible, typically using a temperature of about 240°F (116°

Tin cans preserve most of the nutrients in food. Protein, carbohydrates and fats are not affected, as are vitamins A, C, D and B2. The retention of vitamin B1 depends on the amount of heat used during the canning process. Some vitamins and minerals may dissolve into the brine or syrup in the can during processing, but they retain their nutritional value if those liquids are consumed.

For more information please contact us:

Factory Address: 18 Luy Ban Bich, Tan Thoi Hoa Ward, Tan Phu District, HCMC

Sales department hotline: 028 3961 1587

Marketing: 0857177911

Get a free quote: (Ms. Thao)

Email: Congtybaobimychau@gmail.com