More and more wall paints are packaged in metallic tin packaging. Stability, color matching and airtightness, is becoming more important for tin packaging for the leading wall paint segment. The color of the wall paint is more often than not mixed in the color mixer. That's why it's so important to open and close the packaging easily. Tin packaging is the ideal solution in this market.

Our wall paint tins have openings for use with paint machines and metal mesh straight from the pack. Round paint cans packaging is available.

paint cans

Paint container

Specifications

Circle

Pre-printed on metal packaging, can be decorated

Capacity: 70ml, 100ml, 170ml, 250ml, 375ml, 450ml, 800ml, 3l, 4l, 5l, 17l, 18l, 20l

The interior can be coated with phenol epoxy or gold lacquer

Stackable when full

Suitable for tinting system

Offset printing and digital printing is possible

Round tin packaging for wall paint

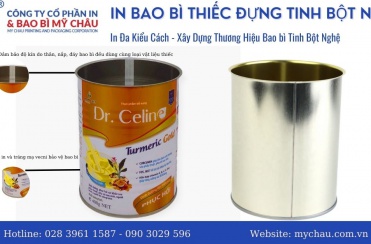

Paint packaging needs to be more and more special and that is now possible with our new rectangular packaging. Our tins are large enough to use with even the largest paint wheelchairs. Tins can have an inner coating so that water-based wall paint can be packaged without problems.

Leather can form with plastic packaging, but tin packaging has made that a thing of the past. There are many decorative possibilities for traditional wall paint packaging.

The lid can be closed quickly and simply by pushing all the corners evenly. It is easy to open and close the lid. Tins are well suited for nesting, due to the recess on the lid.

The advantages of the rectangle are obvious: efficient use of rack space and the ability to print on extremely large packaging surfaces.

The latest printing techniques make this rectangular tin packaging an instant asset in our wall paint packaging collection.

The French market has found many uses for tin.

Paint cans

Paint container

The packaging should also be large enough to use wide wall paints. Easy opening and closing of the packaging (for paint tinting purposes) is also a prerequisite for the operator of the tinting machine. After all, in the professional field, it is the people who operate the tinting machines who have to open many containers in a short time. It goes without saying that the packaging should be sturdy enough for the paint shaker.

For many years, most wall paints were packaged in plastic buckets; Often the difference between the top and bottom wall paints is difficult to discern due to the uniformity.

We have long been offering tin packaging that meets all requirements that anyone can make packaging for wall paint.

The advantages of tin packaging become very obvious: the packaging can have attractive printing, it is stable and can be opened and closed many times without loss of paint quality.

The tin packaging can also be completely emptied, without any residue left behind. It is very simple to open and close the tin without sacrificing the quality of the closing. The lid is secure and can be simply pressed on

Corrosion-resistant gold-plated tin bottom, white coating outside. An inner layer of high-quality paint can handle water-based paints.

In other words: the packaging makes the wall paint stand out, the packaging is of outstanding quality