WHAT IS CANNING WITH TIN CANS?

Canning is a modern preservation method in which food is packed into tin cans or specialized metal containers, then sterilized at high temperatures to destroy spoilage microorganisms.

During this process, air is removed from the can. As it cools down, a vacuum environment is created, preventing bacterial growth and ensuring food remains safe and long-lasting.

WHY CHOOSE TIN CAN PACKAGING?

-

Suitable for various foods: from high-acid products (fruits, vegetables) to low-acid foods (meat, seafood, dairy).

-

Contamination prevention: Hermetic sealing protects products during transportation and storage.

-

Extended shelf life: Canned food can be preserved for up to 3 years without quality loss.

-

Convenient & widely adopted: Canned food has become an essential part of daily consumption in many developed countries.

CANNING PROCESS & PRESERVATION STEPS

The tin canning process typically involves 6 key stages:

-

Cleaning raw materials – Washing with water jets or tanks.

-

Blanching – For vegetables and some fruits, to deactivate enzymes and soften before filling.

-

Filling – Food is placed into cans using automated machines, sometimes with brine or syrup.

-

Sealing – Lids are hermetically sealed using double seam technology.

-

Sterilization – Cans are heated at high temperatures for sufficient time to eliminate microorganisms.

-

Cooling & labeling – Cans are cooled with water or air, then labeled for storage and distribution.

STERILIZATION METHODS

-

High-acid foods (fruits, vegetables, tomatoes…): Sterilized by boiling water.

-

Low-acid foods (meat, seafood, dairy…): Sterilized using steam pressure retorts, ensuring food safety.

ADVANTAGES OF TIN CAN PACKAGING

-

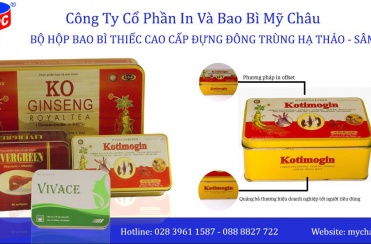

External protection: Durable metal prevents light, moisture, and bacteria penetration.

-

Hermetic sealing: International-standard double seam ensures product integrity.

-

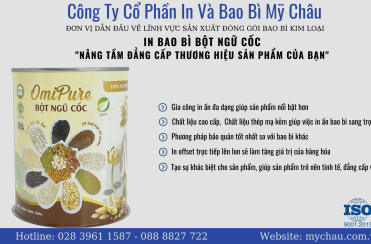

Wide applications: Ideal for seafood, fruits, vegetables, beverages, coffee, tea, and other processed foods.

-

Nutrient retention: Key nutrients such as proteins, carbohydrates, fats, and essential vitamins (A, C, D, B2) are well preserved.

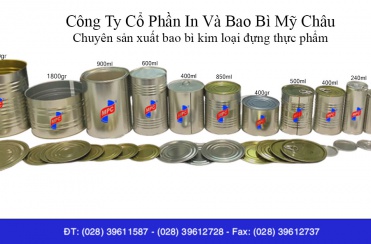

THE EVOLUTION OF TIN CANS

-

In the past: Cans were handmade from tin-plated iron, manually soldered.

-

Today: Modern tin cans are made of 98.5% tin-coated steel, mass-produced by high-speed automatic lines capable of hundreds of cans per minute.

-

New applications: Besides tin cans, aluminum cans are also widely used in the beverage industry thanks to their lightweight, rust-free properties, produced by deep-drawing technology.

CONCLUSION

Tin can packaging remains a safe, effective, and sustainable solution for food preservation. With a closed-loop process and advanced technology, food is not only well-protected but also retains its quality, flavor, and nutritional value.

???? My Chau Packaging – with over 45 years of experience in metal packaging – is proud to deliver international-standard tin can solutions, partnering with businesses in the food & beverage industry.