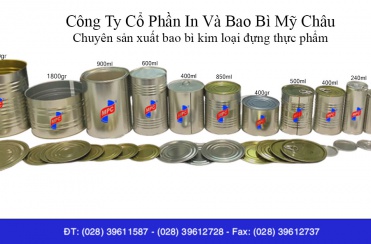

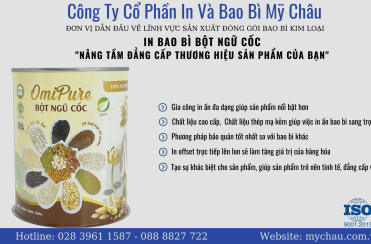

Packaging of Tinplate Cans

Canned food products have become an essential part of modern diets, especially in developed regions. They provide significant value in areas with limited or no refrigeration facilities. Among the most common types of cans used by manufacturers are two-piece cans and three-piece cans.

Canning has long been a popular method for packaging food and beverages thanks to its excellent preservation properties. However, not all cans are the same. While two-piece cans are commonly used for both food and beverages, three-piece cans are mainly applied for food packaging. Understanding these fundamentals is essential when working in the packaging industry.

The rapid changes in the food industry have significantly increased the demand for canned packaging.

A two-piece can is manufactured by drawing a single sheet of metal to form the body and bottom as one unit, with the second end seamed on to complete the package. Because the body and bottom are made from one piece, this type is called a two-piece can.

Two-piece cans are designed to keep packaged food fresh in taste, color, and nutritionally safe while ensuring full commercial sterility required for heat processing. They are widely used for ready-to-eat products and beverages.

Advantages of Two-Piece Cans:

-

Seamless body with no side or bottom seam, ensuring tight sealing and reduced material usage.

-

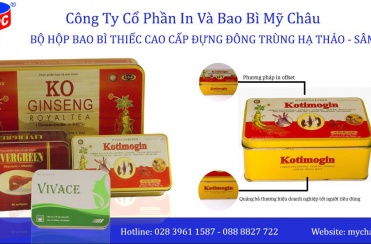

Fully printable surface area for decoration and branding.

-

Simple and efficient manufacturing process.

-

Enhanced by high-barrier coatings, easy-open ends, innovative shapes, and diverse decorative options for brand differentiation.

In addition, two-piece can manufacturers provide a wide range of sizes and materials with eye-catching graphics to deliver optimal packaging solutions. Current market trends focus on die-cut windows, plastic overcaps, and sustainable packaging solutions, with cans being inherently 100% recyclable — a factor that continues to drive growth in the packaging industry.

Cans are used across multiple product categories including beverages, aerosols, paints, foods, and more. Typically made of aluminum or steel, they are primarily available in two main types today: two-piece and three-piece cans. Two-piece cans are produced either through the Draw-and-Redraw (DRD) process or the Draw-and-Iron (DWI) process, and were originally developed as an alternative to three-piece cans.

Tinplate Packaging Quality Standards

Metal ends come in various designs tailored to different product requirements. Metal closures help extend shelf life, and through sterilization and pasteurization processes, they maintain integrity, prevent deformation, and eliminate anaerobic bacteria.

Applications of Two-Piece Metal Cans in the Food Industry

-

Fruits and vegetables

-

Seafood

-

Beverages

-

Tea and coffee

-

Nuts and grains

-

Food ingredients

-

Processed foods

-

Confectionery

-

Dairy products

-

Functional foods and ready-to-eat products

Depending on packaging requirements, specifications may vary in terms of tinplate thickness, tin coating weight, and mechanical properties. Over time, tinplate materials have been developed to be increasingly thinner. This has led to two main approaches: reducing the tin coating or lowering the thickness of the steel base itself. Both methods aim to minimize production costs while maintaining quality.

With ongoing advancements in printing and processing technologies, the applications of tinplate packaging continue to expand. At the same time, reliance on imported tinplate is expected to decrease as domestic production capacity steadily increases.