Advantages and Disadvantages of Metal Packaging

When consulting with our clients, we are often asked: Should we choose 2-piece or 3-piece cans?

The answer is not simple, as the decision depends on many factors and perspectives:

-

From the viewpoint of the can manufacturer or the end user.

-

From the perspective of economics or quality.

-

From appearance, design, presentation, or manageability.

The difference lies in the simplicity or complexity of the manufacturing process, which leads to various approaches. In this article, we will analyze the advantages and disadvantages of metal packaging, focusing on the food industry – where diverse requirements and solutions coexist.

Main Applications of Metal Packaging

In principle, metal packaging can be divided into three main application areas:

1. Beverages

In this sector, the market has almost unanimously adopted the 2-piece can with DWI (Drawn and Wall Ironed) technology. It is the global standard thanks to high-speed production, lightweight structure, and material efficiency. Other packaging types are generally unsuitable.

2. Industrial Products

Industrial packaging requires flexibility in format, sealing types, and accessories. Here, 3-piece cans dominate due to their suitability for low-speed production lines, versatility, and cost-effectiveness.

3. Food

For traditional canned foods (vegetables, meat, fish, seafood…), the choice is more complex. Both 2-piece and 3-piece solutions are available, each with clear advantages and disadvantages depending on the product and process design. This is also the core sector we will focus on in this article.

Main Types of Metal Packaging for Food

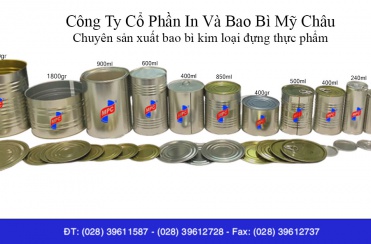

There are three main types:

-

3-piece cans

-

Structure: A rolled body welded and then seamed with top and bottom ends.

-

Advantages: Wide range of sizes, flexible for different food products, easy to produce.

-

Disadvantages: More complex process with multiple seams.

-

-

2-piece cans

-

Structure: Body and bottom are drawn from a single sheet of metal.

-

Advantages: Fewer seams, excellent leak resistance, suitable for high-speed production.

-

Disadvantages: Limited in shape and size options compared to 3-piece cans.

-

-

DRD (Drawn and Redrawn) cans

-

Technology: Redrawing process for stronger, thicker walls.

-

Advantages: High resistance to pressure, excellent food safety.

-

Disadvantages: Higher production costs, fewer suppliers available.

-

Perspectives from Different Stakeholders

-

Manufacturers: Focus on production feasibility, raw material costs, technology, and process stability.

-

Packers (end users): Prefer more suppliers in the market to increase competition on both price and quality. In reality, the supply of 3-piece and 2-piece cans is broader, while DRD cans have fewer suppliers.

-

Consumers: The most critical factor. Packaging must ensure food safety, convenience, long shelf life, and attractive appearance. Consumer benefits should always outweigh those of both manufacturers and packers.

Conclusion

There is no such thing as a “perfect packaging.” Each type of metal packaging comes with its own pros and cons, depending on the application, production scale, and product requirements.

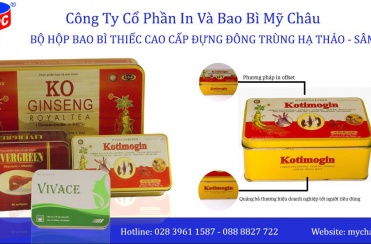

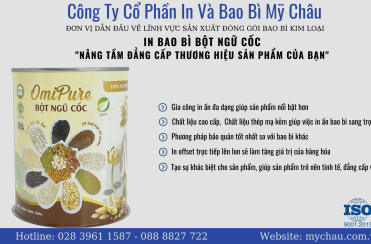

At My Chau, with over 45 years of expertise in metal packaging production and printing, we provide tailored solutions – from 2-piece and 3-piece cans to DRD packaging – ensuring food safety, cost efficiency, and enhanced brand value.