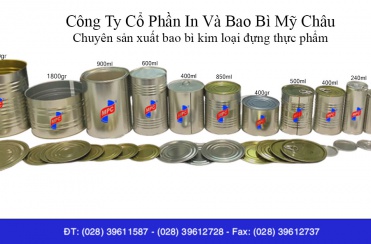

What Products Are Tin Cans Used to Package?

Tin cans are widely used across multiple industries thanks to their durability, protective qualities, and versatility. They not only safeguard products from external factors but also help preserve freshness and quality. Below are the key categories where tin cans are commonly applied:

1. Food Industry

Tin cans are one of the most popular packaging solutions in the food sector, particularly for:

-

Canned foods: fish, meat, fruits, and ready-to-eat meals.

-

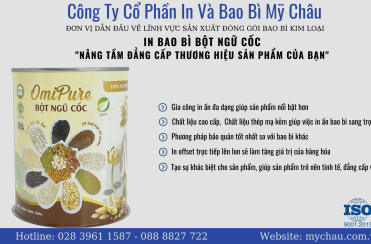

Powdered products: condensed milk, infant formula, cocoa powder, coffee, nutritional powders.

-

Snacks & confectionery: biscuits, candies, nuts.

Benefits for food packaging:

-

Protection against light, moisture, and bacteria.

-

Extended shelf life while maintaining flavor and nutritional value.

-

Strong structure that prevents leakage or damage during transport.

2. Beverage Industry

Tin cans are used for:

-

Soft drinks, juices, energy drinks.

-

Nutritional beverages, nut milk, functional drinks.

-

Beer and carbonated beverages.

Key advantage: Keeps beverages safe, fresh, and convenient for both storage and distribution.

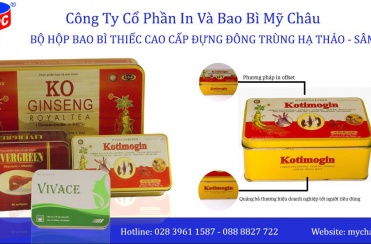

3. Household & Personal Care Products

Tin cans also package a variety of non-food products such as:

-

Cosmetics (e.g., creams, balms).

-

Tobacco products.

-

Gift sets and premium packaging.

4. Industrial Applications

Thanks to their corrosion resistance and durability, tin cans are widely used in:

-

Paints and coatings.

-

Lubricants.

-

Detergents and industrial chemicals.

Case Study: Infant Formula in Tin Cans

Why tin cans are preferred for powdered milk:

-

Moisture protection: Prevents clumping and spoilage.

-

Light resistance: Preserves nutrients from degradation.

-

Hygiene & safety: Keeps out bacteria and mold.

-

Durability: Resistant to shocks during transport.

-

Convenience: Easy-open lids, resealable options, and space-efficient design.

-

Aesthetics: Attractive printing and branding possibilities to enhance shelf appeal.

Packaging process overview:

-

Preparation: Select appropriate tin size and lids.

-

Powder handling: Milk powder is processed, sterilized, and filled under controlled conditions.

-

Sealing: Cans are sealed airtight, often with inert gas flushing for longer preservation.

-

Quality check: Inspect for leakage, sealing integrity, and compliance with food safety standards.

-

Labeling & distribution: Printed designs highlight product information and branding.

Case Study: Canned Foods in Tin Packaging

Process highlights:

-

Cleaning & pre-cooking (if required).

-

Filling into tin cans, followed by air removal or vacuum sealing.

-

Heat sterilization for long-term preservation.

-

Sealing, labeling, and secondary packaging for transport.

Advantages:

-

Extended shelf life due to airtight sealing.

-

Food safety with protection from bacteria and oxidation.

-

Convenience for storage and everyday use.

-

Eco-friendly as tin cans are recyclable.

-

Premium appearance with customizable shapes, colors, and branding.

Conclusion

Tin cans are a versatile and sustainable packaging solution, suitable for food, beverages, cosmetics, pharmaceuticals, and industrial products. With high protection, long shelf life, and excellent branding potential, they remain one of the most trusted packaging choices worldwide.