Printing on Tin Can / Tinplate Packaging for Food

Food packaging plays a vital role in preserving and maintaining nutritional value. Among the most effective and widely used methods is canning.

Over the years, canned food has become an essential part of daily life. The process not only ensures product safety but also prevents the growth of harmful microorganisms.

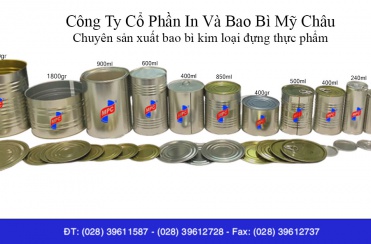

In canning, the two most common types of tinplate cans are 2-piece cans and 3-piece cans. Let’s take a closer look at their features and production processes.

2-Piece Cans

Structure: The body and bottom are formed from a single piece of metal, combined with a separate piece for the top end. 2-piece cans are also known as “drawn cans” and are widely used in the food and beverage industry.

Applications: Commonly used for canned products such as fish, pâté, crab, meat, and often paired with easy-open ends.

Production process:

-

Raw materials: metal coils or sheets.

-

Both sides of the metal are coated with protective varnish.

-

The metal is drawn into a cylindrical body using a press.

-

In addition to round cans, other shapes such as rectangular, oval, or conical can also be produced.

-

Two main forming processes: single-draw and double-draw (DRD – Drawn & Redrawn), with DRD allowing greater height compared to single-draw cans.

3-Piece Cans

Structure: Composed of a body, top, and bottom ends. This is the traditional type of can and remains widely used.

Applications: Commonly used for food products (vegetables, meat, fish, coffee, dry food) and certain non-carbonated beverages such as juices.

Production process:

-

The can body is made from tin-coated steel for easy welding, while the ends may be tinplate, tin-free steel, or aluminum.

-

A protective coating is applied to the steel before cutting out the components.

-

The body is rolled into a cylinder and welded.

-

A protective lacquer (liquid or powder) is applied to the weld seam.

-

The bottom end is seamed to the body.

-

The can is filled with product before the top end is seamed on.

MCP – Trusted Metal Packaging Manufacturer

Canning has become the preferred packaging method thanks to its ability to preserve food safely and extend shelf life. However, as you’ve seen, not all cans are the same:

-

2-piece cans are ideal for seafood and products requiring airtight sealing.

-

3-piece cans are well-suited for dry foods, coffee, and processed vegetables, meat, and fish.

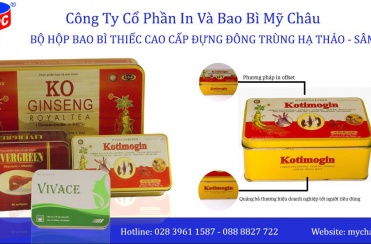

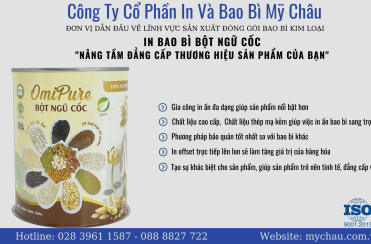

???? If you are looking for a reliable metal packaging partner for food products, My Chau (MCP) is your trusted choice. With over 45 years of experience, MPC provides high-quality tin cans and tinplate packaging certified to international food safety standards. Our advanced printing and coating technology ensures not only food protection but also enhances your brand image in the market.