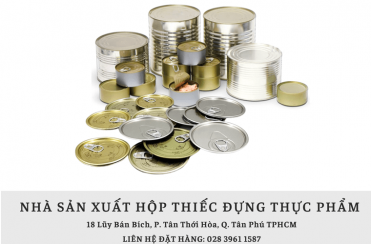

TIN PACKAGING

Metal packaging has grown strongly in recent years with a wide range of shapes, sizes, and designs. The industry continues to research and innovate to meet the increasingly demanding needs of consumers.

FEATURES OF TIN PACKAGING

-

Non-toxic

-

Does not affect the taste or color of food

-

Provides excellent barrier between food and the container

-

Resistant to peeling during sterilization or product preservation

-

High mechanical resistance for production

ADVANTAGES OF METAL PACKAGING

Metal packaging – the “touchpoint” that influences customer demand.

Packaging not only protects products but also conveys the manufacturer’s message to consumers.

The market trend for metal packaging is shifting toward brand recognition and premium product presentation, ensuring uniqueness and brand protection. Metal packaging allows direct printing on metal surfaces.

This innovation enables the production of packaging tailored to each customer’s specific needs, with distinctive forms and features that create a strong visual impact on shelves and deliver real differentiation to end consumers. After all, innovation sells packaging, and packaging sells products.

FIELDS OF METAL PACKAGING PRODUCTION

-

Printing and varnishing on tinplate and aluminum

-

Manufacturing and processing various types of metal packaging, tin packaging printing

-

Metal packaging for food

-

Industrial tin cans for paint, glue, chemicals, solvents, water-based paint, oil-based paint, lubricants, ink

-

Metal boxes: round, square, rectangular

-

Tin boxes for confectionery

-

Tin boxes for coffee, tea, and nuts

-

Cans for fruits: peach, pineapple, longan, papaya, mango, corn, mushroom

-

Tin cans for powdered milk, condensed milk

-

2-piece cans for tuna, sardines, mackerel, crab, shrimp…

-

Packaging for processed food

-

Metal food packaging

-

Product packaging printing

-

Paint packaging printing

-

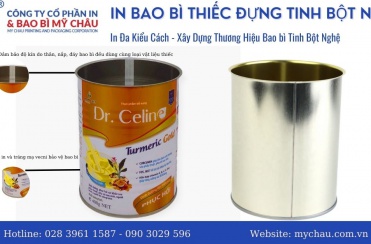

Confectionery packaging printing

-

Coffee packaging printing

-

Tea packaging printing

-

Food packaging printing

-

Paint bucket printing

-

Bottle cap printing