Food packaging plays an important role in the preservation of food. This method is widely known as “canning”.

Over the years, canned foods have become an essential part of everyone's diet. Canning helps to safely preserve food products while preventing microbial deterioration.

In canning, there are two common types of cans that packers use: two-piece cans and three-piece cans. We will discuss these more in this article so keep reading for more!

Print Cans 2 Pieces

In two-piece cans, the bottom and sides of the body are formed using a single piece and another piece for the top. Two-piece cans are also known as pull cans and are mostly used in the food and beverage industry. Packers often use them for sweets that often have sliding lids. They can be made of steel

How to Produce Two Piece Cans

Produce two-piece cans using metal coils or using metal sheets

Both sides of the metal base are usually covered with varnish

The deformation phase of the metal begins with the use of a stamping machine to form a metal shape

In addition to round cans, cans of other shapes (rectangular, oval, conical, etc.) can easily be manufactured. There are two kinds of can forming process, single drawing and double drawing. The type of drawing is sometimes distinctly referred to as a DRD (Draw and Redraw) can, whose height can be higher than that of a single drawing can.

PRINTING LON of 2 PIECES

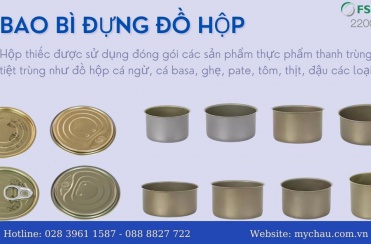

Print Cans Three Pieces

A three-piece can is a traditional can that consists of a lid, body, and bottom. They are commonly used for food packaging but you can also use them for some non-carbonated drinks like juice.

How To Make Three Piece Cans

The three-piece can body is made from tin-coated steel for easier soldering. While the bottom and top can be tinned steel or tinless steel. They can also use aluminum to close the lid easily.

Below is an overview of the three-knife canning process.

The first step is to coat the steel material before cutting the components of the can out of it.

Next is rolling the can to create a cylinder and then welding the seams of the can.

Then, a protective lacquer layer is applied to the seam of the can. Lacquer can be liquid or powder. The bottom of the can is attached to the body. The box is filled with product before the lid is attached